Strategic industrial policy for sustainable development in Africa: the case of cement manufacturing

The article examines the decisive role of vertical industrial policies in fostering Africa's sustainable industrial growth, as proven by Nigeria and Morocco's successful elevation of their cement industries.

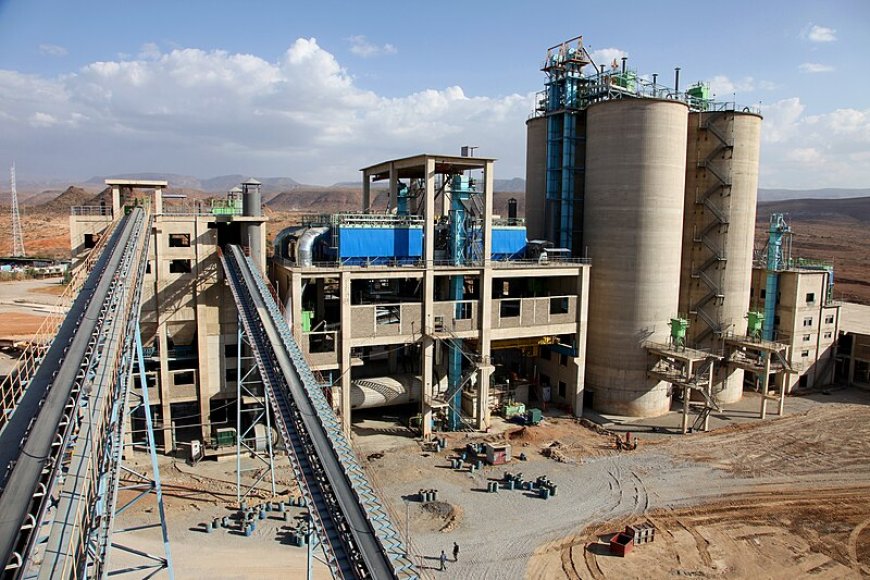

Photo by Gavin Houtheusen/Department for International Development, licensed under CC BY 2.0

Summary

- Urgent industrialisation is needed in Africa to diversify economies, create jobs and address environmental and demographic challenges.

- Successful industrialisation often requires government-led policies, as purely market-driven approaches may not sufficiently support specific industries.

- Effective industrial policy should balance horizontal (broad) and vertical (targeted) measures, focusing on sector-specific support for African development.

- Case studies from Nigeria and Morocco show the significant growth and linkage benefits of vertical industrial policies in the cement industry.

- Industrial policies in Africa should be tailored to each sector's unique context, considering global value chains and local economic factors.

The imperative for industrialisation in Africa

For decades, many African countries have relied on the production and export of primary commodities. Unfortunately, some of these commodities are subject to diminishing returns and perfect competition, leading to extreme price fluctuations and minimal synergy with the local economy. Concurrently, the continent is experiencing a demographic shift characterised by a surge in its young population. This growth exceeds the carrying capacity, resulting in high unemployment and placing a significant strain on the environment (World Bank, 2023). For instance, since the 1960s, Africa has lost two-thirds of its productive land, while its population has increased sixfold (Mrema, 2023). There is an urgent need for African countries to diversify into industries that create employment, reduce poverty and promote sustainable development.

Industrialisation catalyses a series of beneficial linkages within an economy, creating a web of interdependencies that spur further economic and social development. As many scholars have demonstrated, industrialisation does not occur solely through the interplay of market forces (Chang, 2006; Wade, 2015; Whitfield and Buur, 2014). This is due to factors such as market failures, high initial costs and risks, local coordination problems and intense global competition from countries with significant lead advantages (Reinert, 2009). Therefore, governments must drive industrialisation through industrial policies.

Industrial policy refers to government-led initiatives aimed at promoting economic growth and development through the support and regulation of specific industries (Aiginger and Rodrik, 2020). This approach contrasts with a laissez-faire approach, where the market is expected to allocate resources. All countries that have industrialised have implemented some form of government-induced industrial policy (Reinert, 2009). More recently, this includes nations such as China, Singapore, South Korea and, earlier, Japan, among others (Chang, 2003).

Researchers typically categorise industrial policy according to two types: horizontal or vertical (Warwick, 2013). Horizontal policies are strategic measures implemented by governments to provide uniform support across various sectors of the economy. These policies offer several advantages: they reduce favouritism and corruption and may be more accessible for, and therefor benefit, small and medium-sized enterprises. Vertical policies, on the other hand, focus on specific sectors, industries or even particular firms. These policies allow policymakers to select sectors and players, set targets and review results. This enables countries to develop competitive advantages in specific industries, potentially leading to leadership in global markets. South Korea's emphasis on the electronics and automotive industries is a prime example of vertical policies being used to establish a strong international presence. While successful industrial policies typically involve a mix of both horizontal and vertical approaches, in the case of Africa vertical policies are more pertinent to any serious discussion.

Table 1.

Examples of industrial policy instruments

| Policy area | Horizontal approaches | Vertical approaches |

|---|---|---|

| Product market |

|

|

| Capital market |

|

|

|

||

| Technology policies |

|

|

| Labour and skills |

|

|

| Land and infrastructure policies |

|

|

In considering vertical industrial policies, there arises the question of whether African countries, as latecomers to industrialisation, should develop complete production chains within their borders or seek to integrate into regional or global production chains. Some scholars argue that the era of building complete production chains within a country's borders has passed; production is now fragmented, as explained in global value chain (GVC) theories (Gereffi, 2013; Gereffi and Sturgeon, 2013). Countries aiming to industrialise should therefore aim to join an existing value chain and then seek to upgrade within that value chain.

The argument that African countries should focus only on a production segment instead of building a complete chain is sensible when applied to certain sectors (such as textiles, automobiles and electronics) due to the nature of production, technology and market dynamics in these areas. However, it becomes problematic when applied to other sectors. For instance, in some chains, upgrading depends on the discretion of lead firms. The longstanding exportation of raw materials by many African countries exemplifies a form of GVC participation. Ghana and Ivory Coast, for example, have been producing cocoa, a segment in the chocolate production chain, for over a century. Multinational corporations at the top of this chain are unlikely to relocate chocolate production to these countries. Moreover, for countries with sufficient markets, maintaining a complete production chain may be necessary for value retention and creating economic linkages. Given that vertical policies are targeted, any discussion of industrial policy in Africa must adopt a tailored approach that considers local circumstances, changes in the global political economy and the unique nature of the targeted sector.

In examining the practical application of industrial policies, it is crucial to explore instances where such strategies have been successfully implemented. The case studies below provide concrete examples of how targeted industrial policies can transform key sectors and drive broader economic development. The case studies focus on the cement industry, illustrating how Nigeria and Morocco have leveraged vertical industrial policies to achieve significant growth and development.

Case studies: successes and lessons

The cement sector is a vital component of the construction industry, supplying the material needed for building infrastructure such as roads, buildings, bridges and dams. Cement is consumed worldwide, particularly in developing countries with infrastructural deficits where demographic changes are increasing the demand for the material. The cement production chain is a simple process with three main components: extracting raw materials, processing and distribution. Among other factors, the availability of raw materials like limestone will determine development pathways for investors.

As the most populous country in Africa, Nigeria has experienced growing demand for cement (Itaman and Wolf, 2021). In 2002, the government decided to increase domestic production and halt imports through a vertical industrial policy. This policy involved the use of a trade policy tool restricting import licences and granting quotas only to traders/producers who could demonstrate that they were building cement factories in Nigeria. Aiming for self-sufficiency, the government committed to gradually phasing out these quotas as local production increased (Akinyoade and Uche, 2018). Limiting imports to a handful of such traders/producers reduced the risk of investment because investors were assured of a large, ready market for their product. As further support for local cement manufacturing, the government also provided waivers for VAT and custom duties on the importation of cement production equipment, along with tax exemptions.

This policy led to massive investment from producers, resulting in an increase in domestically produced cement: In 2002, the year the policy was implemented, Nigeria produced 2.07 million tons (MT) of cement and imported 6.04 MT (74.5% of domestic consumption); in 2014, the country produced 22.25 MT, amounting to 97% of domestic consumption (Akinyoade and Uche, 2018). Nigeria has since become a net exporter of cement to neighbouring countries. The success of the sector, in terms of increased domestic production, has had numerous linkage benefits: employment, production linkages with other sectors (e.g. boosted production in packaging materials, transportation and logistics) and infrastructure improvements, such as cement companies building concrete roads to ease transportation and supporting the government in constructing hundreds of thousands of homes (see Dangote Cement, 2022).

One of the national giants that emerged due to this policy is Dangote Cement, which has since established subsidiaries in other African countries to become a regional leader. As of 2022, Dangote Cement is Africa’s leading cement producer, with operations in 10 African countries and revenues exceeding US$3.5 billion. In Nigeria alone, Dangote Cement has an annual production capacity of 32.25 million tons per annum (MTa), and across Africa, a total capacity of 51.6 MTa as of 2022. The company’s expansion strategy demonstrates how it is leveraging the GVC approach. For example, in Cameroon, it operates a 1.5 MTa cement grinding facility that opened in 2015—the first new entrant in Cameroon's cement market in 40 years. It has integrated production plants in other countries, such as Senegal and Congo.

Another targeted policy in the cement industry is Morocco's Ciments de l'Atlas (CIMAT), owned by Anas Sefrioui. Sefrioui, a building contractor, builds public housing for the government. His venture into cement production began after his company was awarded a US$1 billion contract by the state to build additional housing units in 2005. CIMAT was established in 2007 as part of an investment agreement between Sefrioui and the Moroccan government. Under this agreement, the government provided the company with tailored policy tools to aid in constructing the first two cement factories, which together have a capacity of 3.2 MT (CIMAT prospectus, 2012).

CIMAT began production in 2010, with the construction industry as one of its main customers. In 2011, the company decided to expand into Sub-Saharan Africa using a GVC approach. It was in this context that Ciments de l’Afrique (CIMAF) was established. By 2013, CIMAF had embarked on grinding and bagging operations in Côte d’Ivoire and Guinea Conakry. In 2014, it launched similar activities in Cameroon and Burkina Faso. The following year, CIMAF began cement grinding in Gabon and grinding and bagging in the Republic of Congo. From 2016 onward, it extended its grinding and bagging activities to Ghana, Mali, Mauritania, Guinea-Bissau and Chad. The group has also expanded into Europe, building its first cement plant in France, which has been operational since 2016. This plant is located in Le Havre (Normandy) and has a capacity of 0.6 MTa.

Policy Lessons and Replicability

The Moroccan strategy represents a form of direct backward integration, where a company begins producing its own inputs. This is akin to a car manufacturer starting to produce its own steel instead of purchasing it from an external supplier, or a consumer with substantial demand opting to build a production unit. More broadly, this approach uses procurement as a tool for industrial policy, offering a straightforward lesson for African countries. In Africa, governments are the largest purchasers of goods and services. For instance, the Nigerian government, at both the federal and state level, spends hundreds of millions of dollars on cars each administration—a sum that could potentially fund the establishment of a local car manufacturing company from scratch.

In Nigeria, the success of the cement industry has led to calls for the government to implement similar policies in many other sectors. Heeding this advice, past Nigerian governments have replicated the same policy tool in other areas, such as a sugar policy known as the Sugar Master Plan. Like the cement policy, the sugar policy restricted licences for the importation of raw sugar from 2013 to companies that could demonstrate production of a replacement product. However, only three investors received the licences and quotas. The policy has since failed, fundamentally because the tool is unsuitable for sugar production (Odijie 2024). For instance, while cement investors only need to control the source of raw materials (limestone), sugar investors must either coordinate thousands of small-scale sugar producers or establish a mechanised sugar estate, both of which present a unique set of coordination challenges. Similarly, Nigeria's tomato paste policy, which adopts the cement model, also faces issues: The factories built as a result of the policy cannot access materials for processing due to coordination problems at the raw material level (The Cable, 2019). This illustrates that a policy suitable for one sector may not necessarily be effective in another.

As African countries continue to forge paths towards economic diversification and industrialisation, the lessons drawn from these experiences emphasise the need for context-specific strategies that consider the unique economic, environmental and social factors of each sector. Furthermore, the importance of the government's role in facilitating industrial growth through supportive policies and initiatives that cater to the distinct needs of their economies cannot be overstated. This approach will be crucial for African nations seeking to harness the full benefits of industrialisation in an increasingly competitive global economy.

About the Author

Michael Ehis Odijie

Dr Michael Ehis Odijie is currently a research fellow in the History Department at University College London. His research interests range from slavery and abolition in Anglophone West Africa to industrial policy and the role of the state in economic change in West Africa.

References

Aiginger, K., & Rodrik, D. (2020). Rebirth of industrial policy and an agenda for the twenty-first century. Journal of Industry, Competition and Trade, 20, 189-207.

Akinyoade, A., & Uche, C. (2018). Development built on crony capitalism? The case of Dangote Cement. Business History, 60(6), 833-858.

Chang, H. J. (2003). Kicking away the ladder: infant industry promotion in historical perspective. Oxford Development Studies, 31(1), 21-32.

Chang, Ha-Joon. (2006). Policy space in historical perspective with special reference to trade and industrial policies. Economic and Political Weekly, 627-633.

CIMAT prospectus. (2012). Retrieved from https://www.ammc.ma/sites/default/files/Summary_CIMAT_EO_23_2012.pdf

Dangote Cement. (2022). Introducing our sustainability pillars. Retrieved from https://dangotecement.com/wp-content/uploads/2022/06/new-Dangote-Cement-2021-Sustainability.pdf

Gereffi, G. (2013). A global value chain perspective on industrial policy and development in emerging markets. Duke Journal of Comparative & International Law, 24, 433.

Gereffi, G., & Sturgeon, T. (2013). Global value chain-oriented industrial policy: the role of emerging economies. In Global Value Chains in a Changing World, pp. 329-360. WTO iLibrary.

Itaman, R., & Wolf, C. (2021). Industrial policy and monopoly capitalism in Nigeria: lessons from the Dangote Business Conglomerate. Development and Change, 52(6), 1473-1502.

Johnson, C. (1982). MITI and the Japanese miracle: the growth of industrial policy, 1925-1975. Stanford University Press.

Mrema, E. (2023). Fostering collaboration to address environmental challenges in Africa. Retrieved from https://www.unep.org/news-and-stories/speech/fostering-collaboration-address-environmental-challenges-africa#:~:text=During%20the%20last%2070%20years,and%20security%20of%20the%20countries

Odijie, M. (2024). Nigeria's sugar master plan: Ignoring losers from industrial policy can be costly. Development Policy Review, e12752.

Reinert, E. S. (2019). How rich countries got rich... and why poor countries stay poor. Hachette UK.

The Cable. (2019). Again, Dangote’s tomato processing factory shuts down. Retrieved from https://www.thecable.ng/dangote-tonne-tomato-paste-factory-shuts-down-again

Wade, Robert. (2015). The role of industrial policy in developing countries. Rethinking development strategies after the financial crisis, 1: 67-78.

Warwick, K. (2013). Beyond industrial policy: emerging issues and new trends. OECD Science, Technology and Industry Policy Papers, No. 2, OECD Publishing, Paris.

Whitfield, L. & Buur, L. (2014). The politics of industrial policy: ruling elites and their alliances.Third World Quarterly,35(1), pp.126-144.

World Bank. (2023). Investing in youth, transforming Africa. Retrieved from https://www.worldbank.org/en/news/feature/2023/06/27/investing-in-youth-transforming-africa